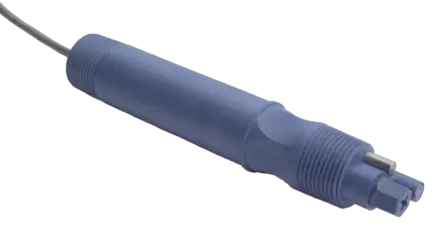

Oxidation Reduction Potential

Dosage and ORP

Automated ozone dosage is controlled primarily through ORP (Oxidation-Reduction-Potential), which is a measurement of how much oxidant is in solution . Purifico offers the flexibility to program dosage based on schedule and/or ORP to suit various systems and irrigation strategies.

Home » ORP